Cyclones a'swirling,

Round and round the small bits go,

A crowd is welcome

Been struggling a while now at work trying to a consistent vacuum flow working in a dirty environment. Most vacuums (that I've come across, set up, and tested) pull air through some filter that captures the dirty particulates to be captured. The filter both protects the filter and stops any of the particulates from escaping back into the air. As much as we'd like to ignore the agonized squeal of the motor in the un-serviced vacs we bought in the happier (and cleaner) past times, filters get clogged, decreasing the airflow over time. For a regular shop vac in standard, intermittent use-cases, that's unlikely to be a huge deal, but when utilizing these suckers continuously for much smaller particles, performance would be irregular at best even with frequent maintenance.

Enter the cyclone separator: an add-on unit between the inlet and vacuum motor that pulls bigger particles out of the air stream before hitting the filters at all. It's typically a conical unit pulling air flow through the center of the column, with the inlet stream entering the cone in an orthogonal direction, tangential to the curve of the cone. Combination of the conservation of mass and the weight of the particles directs them downwards and out instead of up through the central airflow to the motor. The most basic commercial offering is probably the Dust Deputy, but many variations exist, with some striving to minimize the space occupied by the add-on [1][2] or interface more easily with popular vacuums. The addition of the cyclone separator can end up being quite large and are more often found in stationary setups in woodworking shops.

Even though sawdust particles are quite small, and woodworking cyclone separators are optimized for such particles, they're not foolproof, as evidenced by the retention of filters in the vacuum subsystem, in handheld and stationary systems alike. This seems to be the primary struggle for so-called bagless vacuum cleaners, which either use a removable rigid filter (that can and should be cleaned regularly) or in Dyson's case, a multitude of small cyclone separators packaged as densely as possible. James Dyson perhaps summarizes their innovations most succinctly: they've miniaturized cyclone separation technology to maintain airflow/suction when picking up dust.

Other videos showing off more details on multi-cyclone separators:

- Dyson Root Cyclone w/ Core Separator

- Explaining/Showing Multi Cyclonic System Inside and Out

- Dyson Cinetic Technology is Amazing

- The technology behind the Dyson DC59 cordless vacuum cleaner

- Dyson 2015 | Dyson Cinetic Canister Vacuum Cleaner | Cinetic Science Explained

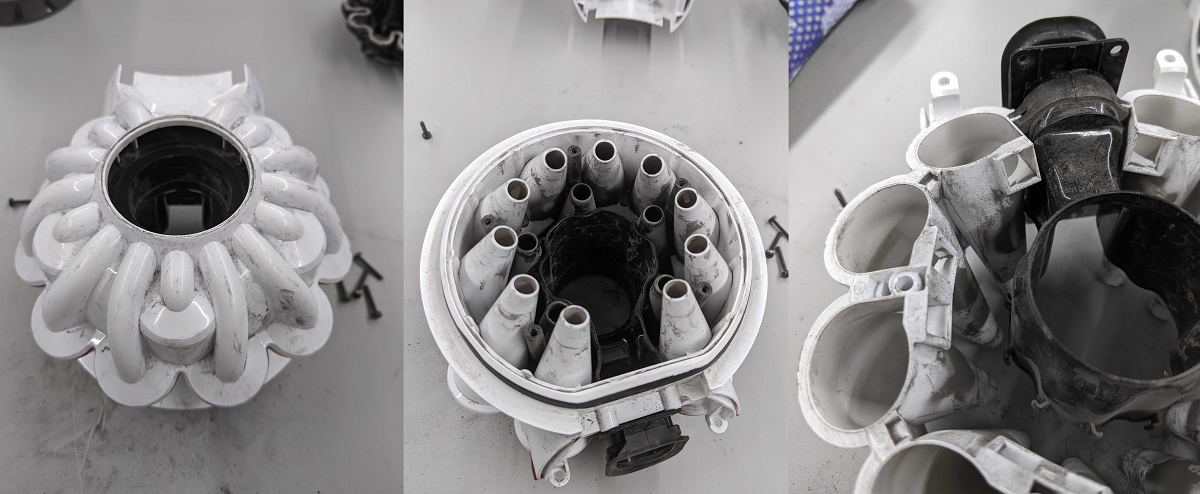

This thing is really small when compared to the cyclone separator add-ons you'd find at Home Depot. Granted, it's not meant to fill up barrels in a workshop and needed to be handheld, but it's still pretty spectacular the functionality that they've managed to shrink down into these collection of funnels. There's a total of 15 mini cyclone separators, surrounding a central filter sitting between the separator outputs and the vacuum motor. If you stare at the central axis of the canister, there are effectively 'zones' going from the outside to the center:

- outer suction zone for large particles blocked by the metal mesh

- inner suction zone leading to the small tangential ports of the cyclone separators

- exit annulus for particles coming out of the mini cyclone separators

- sealed channel for the vacuum source leading to the top of the separators

The air path is pretty convoluted, and I wonder if that's a consequence of the packaging requirements or if the extended effective length helps even out the airflow across the multiple separators in some way. The air first enters the dirt canister region at an offset, tangential to the outer contour, on the outside of the metal filter. On the interior of the metal filter, there's an annular region leading to a void that connects to the each of the tangential inlet channels for the conical separators. Each conical separator has a top outlet port that connects to yet another void in the center of the canister that leads to the vacuum source, sealed with a rubber grommet of sorts. The tip of the conical separators all dump into another annular region that connects back to the dirt canister volume.

The path to the inlets of the cyclone separators seems particularly messy and haphazard, which (to me) is further evidenced by how easily the dirt/powder builds up around the conical tips. I suppose that maybe the manufacturers are ok with the dust getting caught prior to the separators, since that still keeps the particles in the canister and doesn't clog any of the filter elements that may compromise the vacuum air flow? I would've loved to see the earlier prototypes that (presumably) had less tortuous air paths.

The injection molding and custom gasket work is pretty intense, so perhaps that explains we don't see this style of separator too often elsewhere, but it does make me wonder how far we can take this technology by continuing to make the separators smaller and more numerous. Seems like an interesting use case for 3d printing if only for testing/evaluation, and intuitively, I feel that we can get the performance a lot better with smoother/straighter airflow paths that don't need to be compromised to satisfy packaging constraints.

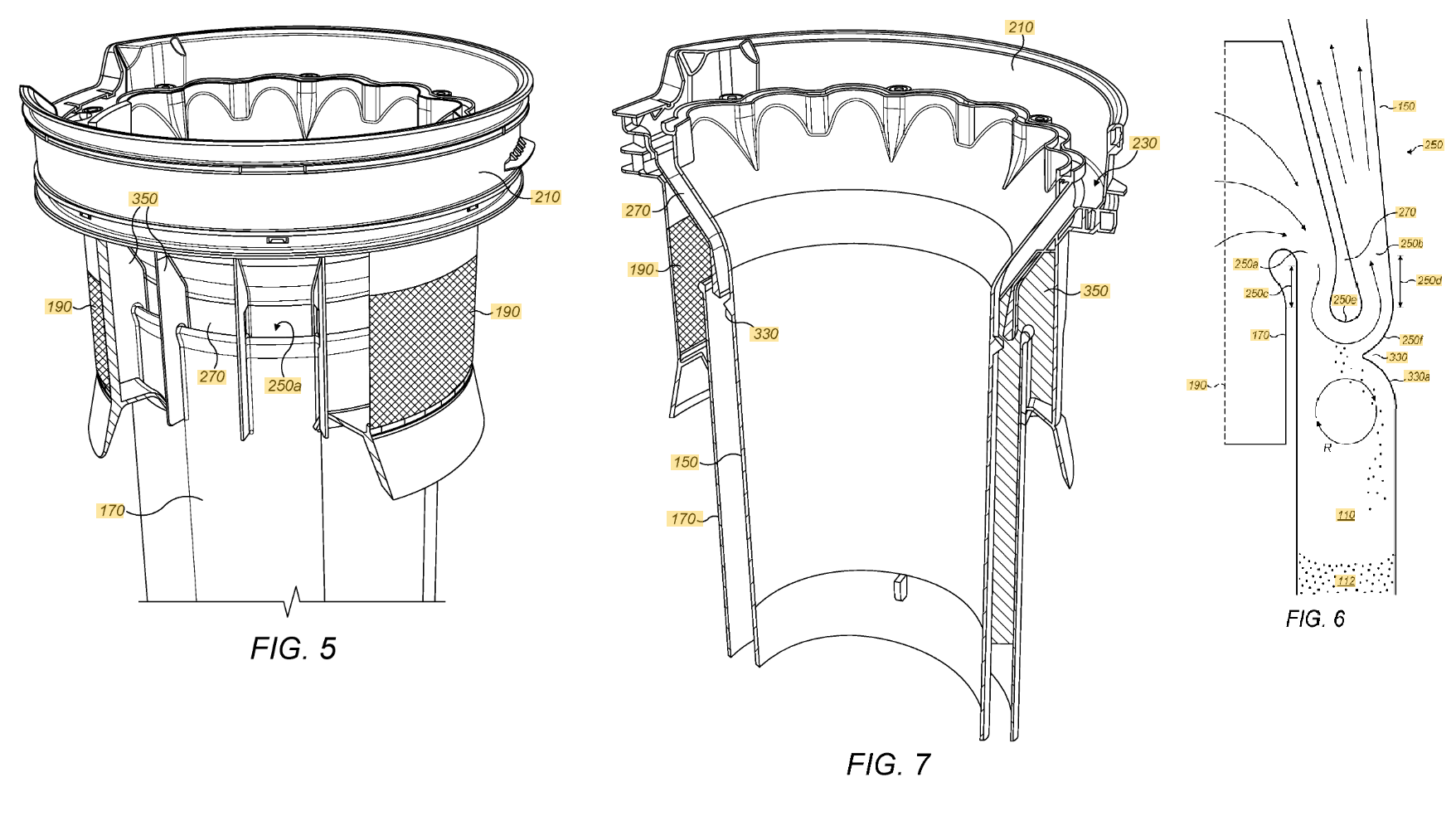

2022-11-17 EDIT - Snapshots from Patents

This teardown wasn't of some random Aliexpress purchase, and there's an opportunity here to go through some nifty patent images for better insight. It appears to me that the Dyson separator arranges their chambers a bit differently from conventional multi-cyclone separators.

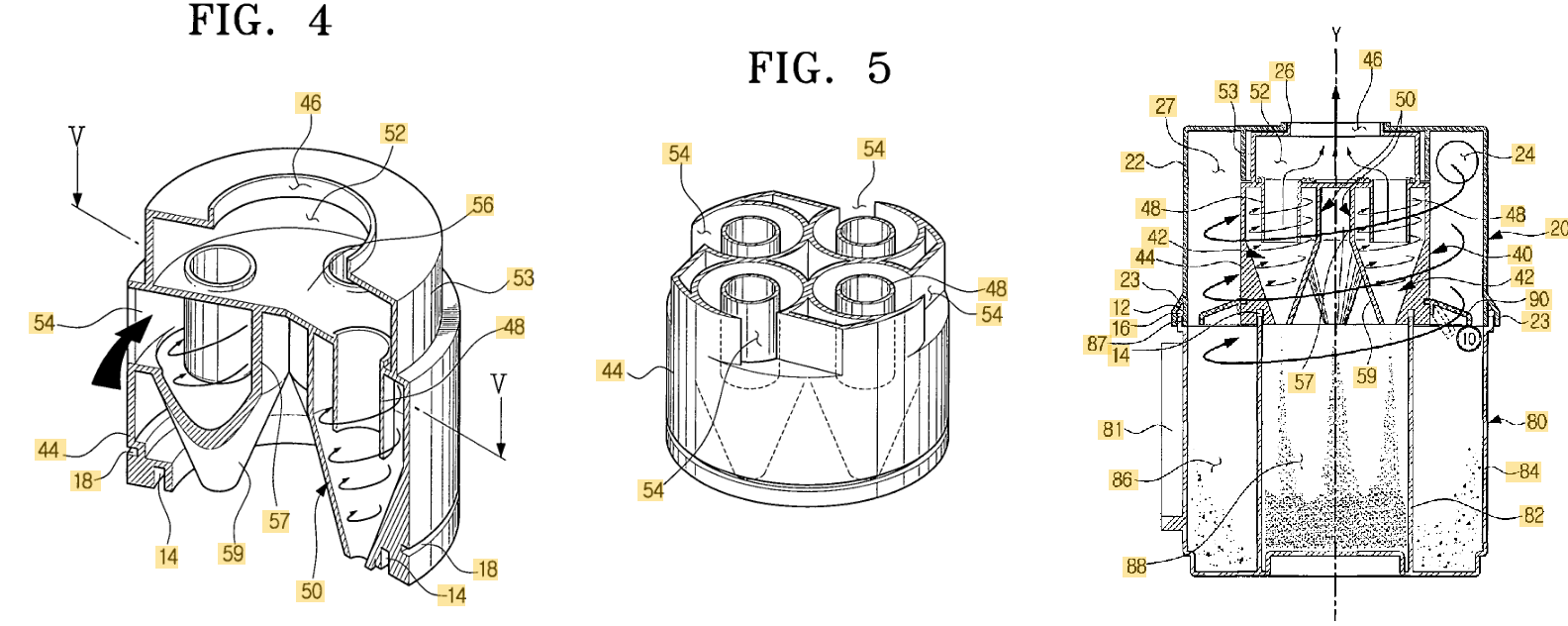

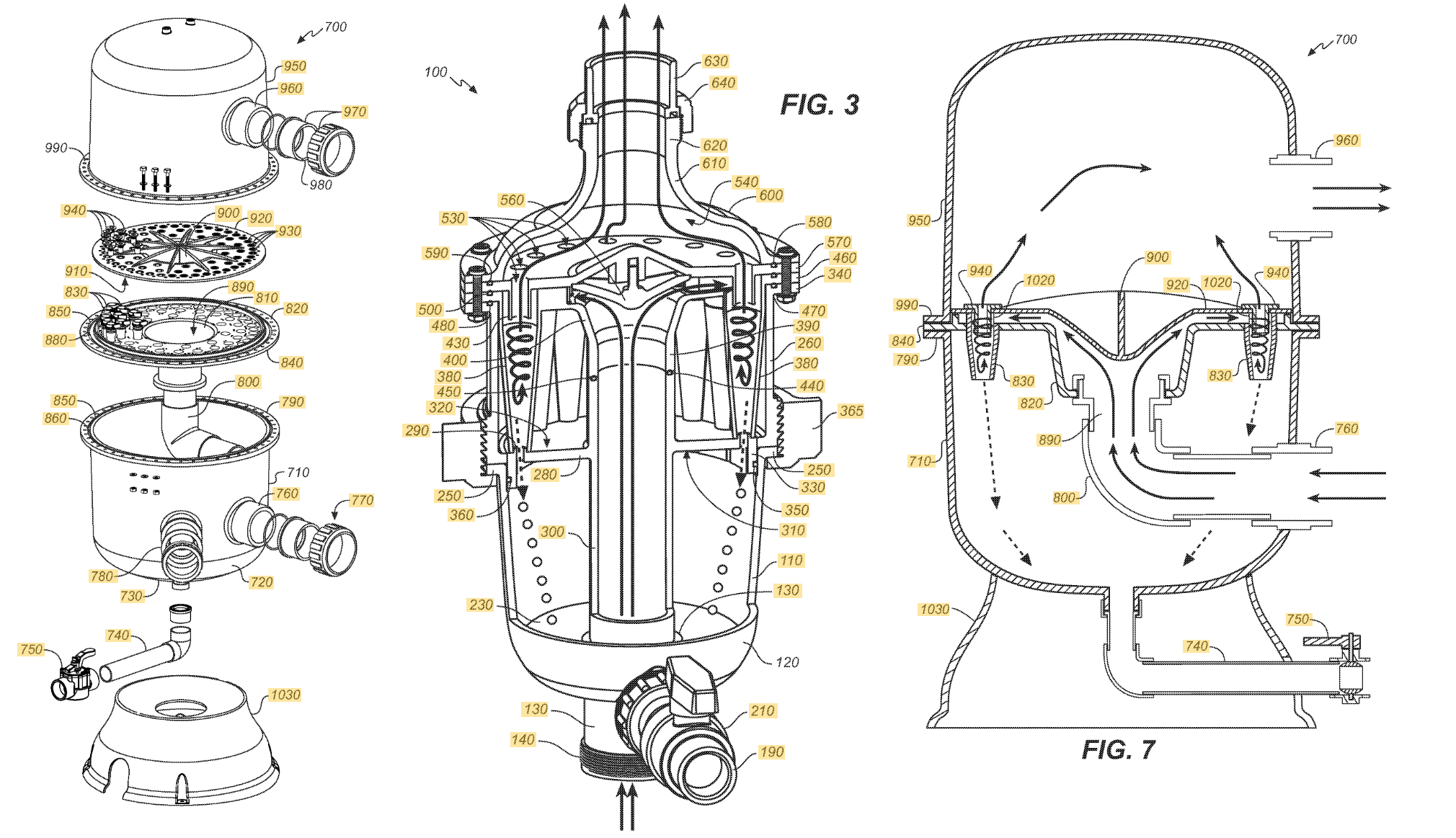

For conventional multi-cyclone separators (patents US7771499 and US9016480B2, for example), it appears that the cyclone sits in serial between the inlet and the vacuum, meaning that whatever is picked up passes through the separator entirely before falling into the waste chamber. The flow pathway makes intuitive sense where the outlet of the cyclones are unlikely to get clogged.

However, in moving to smaller and smaller cyclones in an attempt to capture smaller dust particles without the use of a bag/filter, there's a higher chance of the cyclones getting clogged, despite the fancy vibration analysis Dyson mentions in their Youtube videos above. As such, it looks like there's a bit of a tortuous path added between the inlet to the separators and the waste chamber, so that bigger particles can skip the cyclones altogether. Patent US9603498B2 seems to illustrate this the best. As long we maintain enough suction that provides a net pull on the dirt we're picking up, the tortuous path around the outermost metal mesh seems to be enough to knock the bigger particles directly into the waste chamber by leveraging the momentum of the dirt particles in a similar way to how the cyclone normally work.